Scientists and engineers recognize an elusive but profound difference between precision and accuracy. The two qualities often go hand in hand, of course, but precision involves an ideal of meticulousness and consistency, while accuracy implies real-world truth. When a sharpshooter fires at a target, if the bullets strike close together—clustered, rather than spread out—that is precise shooting. But the shots are only accurate if they hit the bull’s eye. A clock is precise when it marks the seconds exactly and unvaryingly but may still be inaccurate if it shows the wrong time. Perversely, we sometimes value precision at the expense of accuracy.

Simon Winchester, whose The Perfectionists ventures a history of this abstract concept, offers another way of looking at the distinction: a Rolls-Royce automobile, the 1984 Camargue model. In the course of a story filled with wonderful machines of every type, Winchester reveals himself to be something of a Rolls-Royce fanboy, but he declares this one to have been an ugly behemoth:

While the engineers had lovingly made yet another model of a car that enjoyed great precision in every aspect of its manufacture, those who had commissioned and designed and marketed and sold it had no feel for the accuracy of their decisions.

Winchester is a longtime journalist turned author, a meticulous researcher and catholic thinker who has written superb books about The Oxford English Dictionary, the Krakatoa eruption, the birth of modern geology, and (separately) the Atlantic and Pacific Oceans. Compared with topics like those, precision may seem an odd choice. What does it mean to write a history of so abstract a concept? Where does it even begin?

First Winchester needs to convince us that precision is a thing. It is, he tells us, a component of machines, and for that matter “an essential component of the modern world,…invisible, hidden in plain sight.” Besides being a component, it is a “phenomenon” that has transformed human society. We take it for granted, like the air we breathe, though we are suckers for precision snow tires and precision beard trimmers and we aspire to precision medicine and precision tattoo removal. It is “an essential aspect of modernity that makes the modern possible,” Winchester writes:

Precision is an integral, unchallenged, and seemingly essential component of our modern social, mercantile, scientific, mechanical, and intellectual landscapes. It pervades our lives entirely, comprehensively, wholly.

Which of the sciences are the most precise? Biology is messy, a science of divergence and variation, of creatures in all shapes and sizes. “Astronomical precision” is an oxymoron, astronomy being full of approximations and guesses piled atop one another—although the instruments of astronomy are tools of increasing and, lately, astounding precision. Mathematical precision trumps astronomical precision; mathematics is precise by definition. Winchester is not exploring the world of abstractions, though, but the real world, where people make things. His father was a precision engineer who turned metal into the most perfect machinery possible. Wood is nice but imprecise. The story of precision begins with metal.

And the story begins, according to Winchester, at a specific place and time: North Wales, “on a cool May day in 1776.” The Age of Steam was getting underway. So was the Industrial Revolution—almost but not quite the same thing. In Scotland, James Watt was designing a new engine to pump water by means of the power of steam. In England, John “Iron-Mad” Wilkinson was improving the manufacture of cannons, which were prone to exploding, with notorious consequences for the sailors manning the gun decks of the navy’s ships. Rather than casting cannons as hollow tubes, Wilkinson invented a machine that took solid blocks of iron and bored cylindrical holes into them: straight and precise, one after another, each cannon identical to the last. His boring machine, which he patented, made him a rich man.

Watt, meanwhile, had patented his steam engine, a giant machine, tall as a house, at its heart a four-foot-wide cylinder in which blasts of steam forced a piston up and down. His first engines were hugely powerful and yet frustratingly inefficient. They leaked. Steam gushed everywhere. Winchester, a master of detail, lists the ways the inventor tried to plug the gaps between cylinder and piston: rubber, linseed oil–soaked leather, paste of soaked paper and flour, corkboard shims, and half-dried horse dung—until finally John Wilkinson came along. He wanted a Watt engine to power one of his bellows. He saw the problem and had the solution ready-made. He could bore steam-engine cylinders from solid iron just as he had naval cannons, and on a larger scale. He made a massive boring tool of ultrahard iron and, with huge iron rods and iron sleighs and chains and blocks and “searing heat and grinding din,” achieved a cylinder, four feet in diameter, which as Watt later wrote “does not err the thickness of an old shilling at any part.”

Advertisement

By “an old shilling” he meant a tenth of an inch, which is a reminder that measurement itself—the science and the terminology—was in its infancy. An engineer today would say a tolerance of 0.1 inches.

James Watt’s fame eclipses Iron-Mad Wilkinson’s, but it is Wilkinson’s precision that enabled Watt’s steam engine to power pumps and mills and factories all over England, igniting the Industrial Revolution. As much as the machinery itself, the discovery of tolerance is crucial to this story. The tolerance is the clearance between, in this case, cylinder and piston. It is a specification on which an engineer (and a customer) can rely. It is the foundational concept for the world of increasing precision. When machine parts could be made to a tolerance of one tenth of an inch, soon finer tolerances would be possible: a hundredth of an inch, a thousandth, a ten-thousandth, and less.

Watt’s invention was a machine. Wilkinson’s was a machine tool: a machine for making machines and their parts. More and better machines followed, some so basic that we barely think of them as machines: toilets, locks, pulley blocks for sailing ships, muskets. The history of machinery has been written before, of course, as has the history of industrialization. These can be histories of science or economics. By focusing instead on the arrow of increasing precision, Winchester is, in effect, walking us around a familiar object to expose an unfamiliar perspective.

Can precision really be a creation of the industrial world? The word comes from Latin by way of middle French, but first it meant “cutting off” or “trimming.” The sense of exactitude comes later. It seems incredible that the ancients lacked this concept, so pervasive in modern thinking, but they measured time with sundials and sandglasses, and they counted space with hands and feet, and the “stone” has survived into modern Britain as a measure of weight.

Any assessment of ancient technology has to include, however, a single extraordinary discovery—an archaeological oddball the size of a toaster, named the “Antikythera mechanism,” after the island near Crete where Greek sponge divers recovered it in 1900 from a shipwreck 150 feet deep. Archaeologists were astonished to find, inside a shell of wood and bronze dated to the first or second century BC, a complex clockwork machine comprising at least thirty bronze dials and gears with intricate meshing teeth. In the annals of archaeology, it’s a complete outlier. It displays a mechanical complexity otherwise unknown in the ancient world and not matched again until fourteenth-century Europe. To call it “clockwork” is an anachronism: clocks came much later. Yet the gears seem to have been made—by hand—to a tolerance of a few tenths of a millimeter.

After a century of investigation and speculation, scientists have settled on the view that the Antikythera mechanism was an analog computer, intended to demonstrate astronomical cycles. Dials seem to represent the sun, the moon, and the five planets then known. It might have been able to predict eclipses of the moon. Where planetary motion is concerned, however, it seems to have been highly flawed. The engineering is better than the underlying astronomy. As Winchester notes, the Antikythera mechanism represents a device that is amazingly precise, yet not very accurate.

What makes precision a feature of the modern world is the transition from craftsmanship to mass production. The genius of machine tools—as opposed to mere machines—lies in their repeatability. Artisans of shoes or tables or even clocks can make things exquisite and precise, “but their precision was very much for the few,” Winchester writes. “It was only when precision was created for the many that precision as a concept began to have the profound impact on society as a whole that it does today.” That was John Wilkinson’s achievement in 1776: “the first construction possessed of a degree of real and reproducible mechanical precision—precision that was measurable, recordable, repeatable.”

Perhaps the canonical machine tool—surely the oldest—is the lathe, a turning device for cutting and shaping table legs, gun barrels, and screws. Wooden lathes date back to ancient China and Egypt. However, metal lathes, enormous and powerful, turning out metal machine parts, did not come into their own until the end of the eighteenth century. You can explain that in terms of available energy: water wheels and steam engines. Or you can explain it as Winchester does, in terms of precision. The British inventor Henry Maudslay made the first successful screw-cutting lathe in 1800, and to Winchester the crucial part of his invention is a device known as a slide rest: the device that holds the cutting tools and adjusts their position as delicately as possible, with the help of gears. Maudslay’s lathe, described by one historian as “the mother tool of the industrial age,” achieved a tolerance of one ten-thousandth of an inch. Metal screws and other pieces could be turned out by the hundreds and then the thousands, every one exactly the same.

Advertisement

Because they were replicable, they were interchangeable. Because they were interchangeable, they made possible a world of mass production and the warehousing and distribution of component parts. A French gunsmith, Honoré Blanc, is credited with showing in 1785 that flintlocks for muskets could be made with interchangeable parts. Before an audience, he disassembled twenty-five flintlocks into twenty-five frizzle springs, twenty-five face plates, twenty-five bridles, and twenty-five pans, randomly shuffled the pieces, and then rebuilt “out of this confusion of components” twenty-five new locks. Particularly impressed was the American minister to France, Thomas Jefferson, who posted by packet ship a letter explaining the new method for the benefit of Congress:

It consists in the making every part of them so exactly alike that what belongs to any one, may be used for every other musket in the magazine…. I put several together myself taking pieces at hazard as they came to hand, and they fitted in the most perfect manner. The advantages of this, when arms need repair, are evident.

As it was, when a musket broke down in the field, a soldier needed to find a blacksmith.

Replication and standardization are so hard-wired into our world that we forget how the unstandardized world functioned. A Massachusetts inventor named Thomas Blanchard in 1817 created a lathe that made wooden lasts for shoes. Cobblers still made the shoes, but now the sizes could be systematized. “Prior to that,” says Winchester, “shoes were offered up in barrels, at random. A customer shuffled through the barrel until finding a shoe that fit, more or less comfortably.” Before long, Blanchard’s lathe was making standardized gun stocks at the Springfield Armory and then at its successor, the Harpers Ferry Armory, which began turning out muskets and rifles by the thousands on machines powered by water turbines at the convergence of the Shenandoah and Potomac Rivers. “These were the first truly mechanically produced production-line objects made anywhere,” Winchester writes. “They were machine-made in their entirety, ‘lock, stock, and barrel.’” It is perhaps no surprise that the military played from the first, and continues to play, a leading and deadly part in the development of precision-based technologies and methods.

The same methods that enabled mass production of guns led to sewing machines, combine harvesters, and bicycles. By the time of the American Civil War, precision engineers in England had learned to machine metal to a tolerance of a millionth of an inch. High-velocity rifles followed, and precision timepieces. A new century, a few more orders of magnitude, and then automobiles. On one side of the Atlantic, Winchester admires the Silver Ghost of Henry Royce and Charles Rolls, “the nonpareil, the exemplar of all that is right about engineering accomplished to the very highest of standards, and with the highest level of precision.” On the other side, though, Henry Ford was advertising his Model A—“made of few parts, and every part does something”—successor to the “Tin Lizzie” Model T, to be followed by the Models B, C, F, K, and N. During the same period that the Rolls-Royce factory turned out almost eight thousand Silver Ghosts, Ford made more than 16 million of his motorcars.

His true invention, of course, was the assembly line. And though his car was by comparison crude and cheap and unreliable, it was Ford, not Rolls and Royce, who demanded the utmost precision. The assembly line depended on replication, a flow of parts reliably the same, perfectly interchangeable. Removed from the equation: the need for human craftsmanship.

At the beginning of the nineteenth century the Luddites, named after a possibly mythical weaver called Ned Ludd, smashed stocking frames—knitting machines—that imitated the motions of human weavers and, with increasing efficiency, put them out of work. The Luddites were victims of precision, and they weren’t the last. At the Portsmouth dockyards, Henry Maudslay’s machines replaced a hundred skilled artisans. There, as Winchester notes, precision “seemed to benefit those with power; it was a troubling puzzlement to those without.” Automation replaced artistry. Interchangeable parts—copies, by definition—drained work of craftsmanship. In effect they turned artisans into machines themselves. The French were more inclined to resist this trend than the British, but the march of progress was inexorable. “By superseding labour the country is depopulated and filled with machines,” wrote the mathematician and engineer Charles Dupin, and The Economist retorted in 1852:

The reverse is the fact. England is not depopulated, and it is by using and employing more and more machinery, that her people are nourished and increase in numbers as well as in wealth. They borrow the powers of nature and obtain food in abundance, while the French can scarcely live, and the Irish are starved.

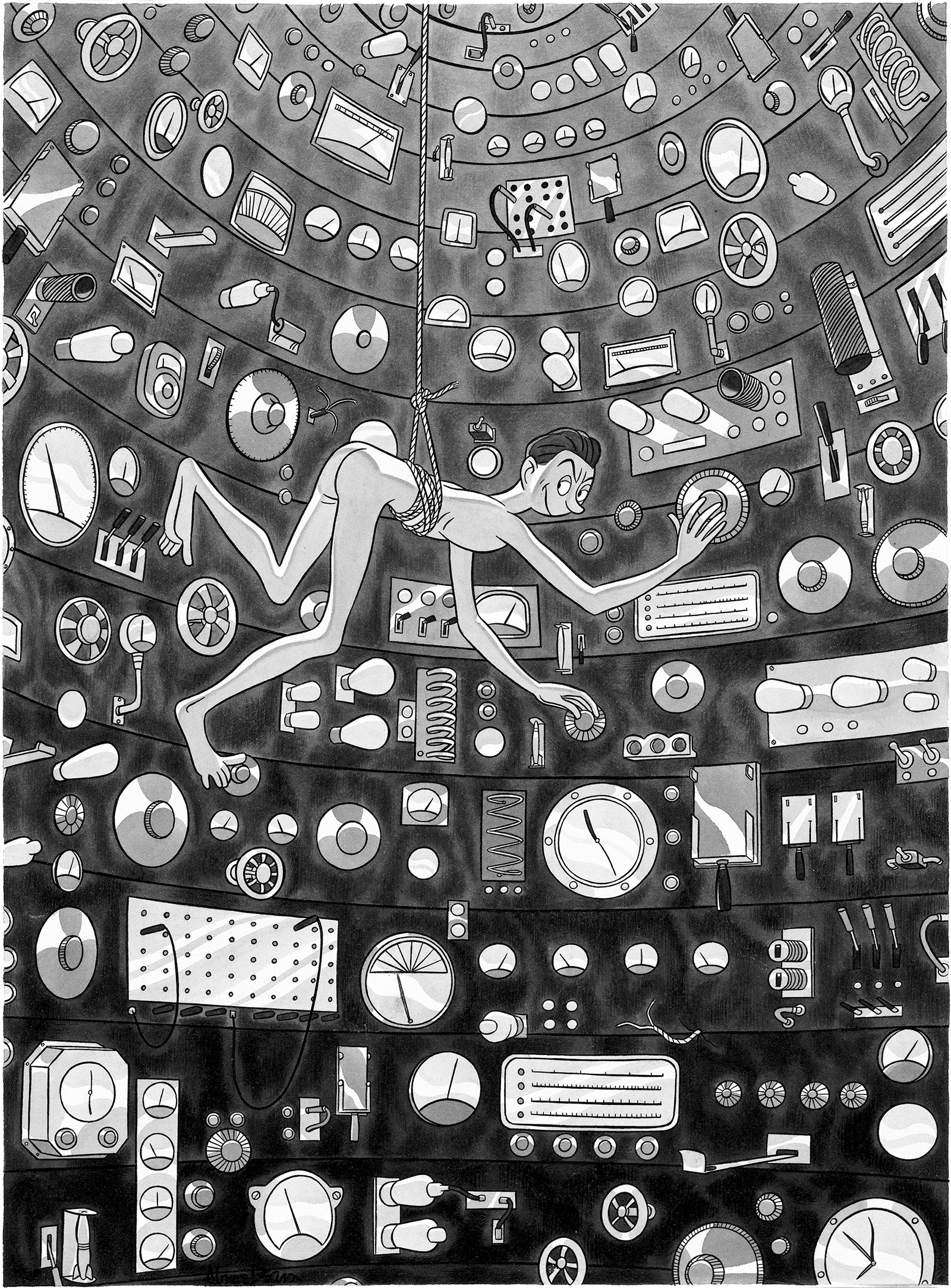

How can engineers resist the ever finer, ever more exact, ever more perfect technologies that come from pushing the bounds of mechanical possibility? A modern jet engine is a colossus of mass and power, weighing eight tons and delivering five times that in thrust, but its essential quality is precision: for its blades to spin thousands of times per minute, free of vibration, amid a roaring blaze of jet fuel and compressed air, requires microscopic tolerances beyond the limits of human skill. Automation and robotics are no longer optional. “Precision engineering,” says Winchester, “does now appear to have reached some kind of limit, where the presence of humans, once essential to maintaining the attainment of the precise, can on occasion be more of a drawback than a boon.”

Metal gives way to glass: the eight-foot primary mirror of the Hubble Space Telescope is polished to a smoothness of less than a millionth of an inch. Yet the mission began disastrously in 1990: a minute flaw in a laser measuring device, a deviation one fiftieth of the thickness of a human hair, initially caused a catastrophic defect called spherical aberration that prevented the mirror from focusing precisely and required a repair mission three years later.

Glass gives way to silicon: the smoothing and layering and etching of integrated circuits has taken precision to submicroscopic levels. The transistors on modern chips are invisible, smaller than the smallest bacteria, and approaching the dimensions of atoms. The superlatives of precision start to outrun the power of even Winchester’s prose: “edge-of-the-seat, leading-edge, bleeding-edge ultrasubmicroscopic precision.” Precision applies to time as well as space. The atomic clocks that synchronize the world’s networks—and enable navigation by GPS—keep time in perfect nanoseconds.

But when does perfectionism become pathology? Maybe precision is a thing we have come to fetishize. Collectors of Leica cameras and Swiss watches, audiophiles in search of the perfect gold-plated speaker cable, devotees of titanium pocket knives and pens—at some point the hunger for ever-increasing precision resembles a cult. Winchester sees this. His paean to perfectionism finally throws itself into reverse and rediscovers the virtues of imprecision. He suggests a need for balance and looks to Japan, a country that worships precision but also continues to revere the patient craftsmanship of hand tools and natural materials. Japan gives us the term wabi-sabi, the acceptance of imperfection, asymmetry, and incompleteness.

“Humankind,” says Winchester,

obsessed and impressed today with the perceived worth of the finely finished edge and the perfectly spherical bearing and by degrees of flatness that are not known outside the world of the engineer, would perhaps do well similarly to learn to accept the equal significance, the equal weight, of the natural order.

As we approach what must be physical limits on precision—engineers can contemplate the Planck length, where quantum uncertainty overtakes classical measurement—we may recognize psychological limits, too.